Cancer

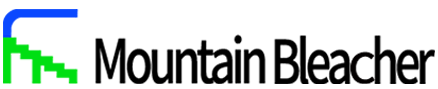

34″ Back height, Blow Molded Seat and Back

Seats and backs: Double wall blow-molded high-density polyethylene with anti-static compound and ultra-violet stabilizing additives.

Die cast aluminum standards with integral end panels and armrests, with recess for optional aisle plates.

Contoured, structural-steel seat hinge arm, recessed into the double wall blow-molded high-density polyethylene seat.

Seat hinge arms rotate on a hinge pivot shaft fitted with permanently lubricated polymer bearings and spring lift system.

Colors selected from Manufacturers standard colors.

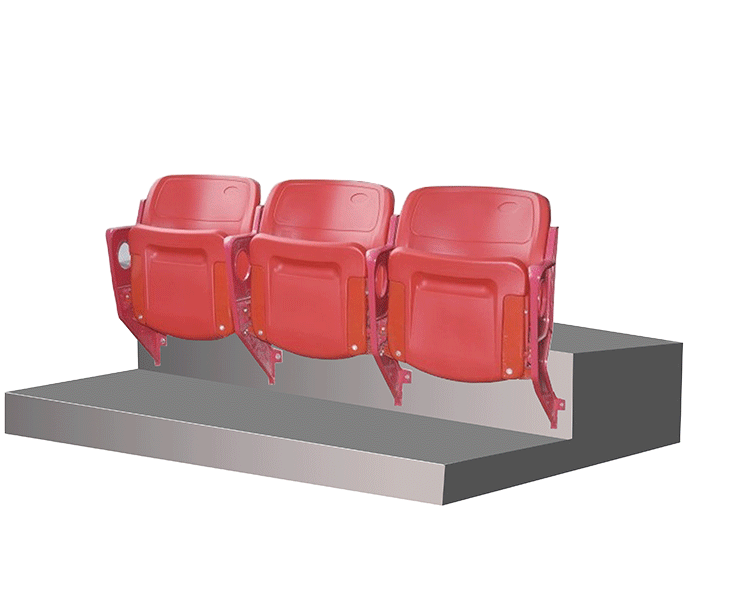

34″ Back height, Blow Molded Seat and Back

Seats and backs: Double wall blow-molded high-density polyethylene with anti-static compound and ultra-violet stabilizing additives.

Die cast aluminum standards with integral end panels and armrests, with recess for optional aisle plates.

Contoured, structural-steel seat hinge arm, recessed into the double wall blow-molded high-density polyethylene seat.

Seat hinge arms rotate on a hinge pivot shaft fitted with permanently lubricated polymer bearings and spring lift system.

Colors selected from Manufacturers standard colors.

Mouting Options

Floor mount, flat or tiered, riser mount, telescopic, movable ganged in sets of 3 or 4, straight row or radius, Single unit movable.

Seat construction

Seating must be constructed in accordance with ASTM certified assembly process, under ISO 9001 guidelines, fabricator must demonstrate QC and testing processes and management.

Foam

Fabric attached over 1/4″ backer board, w/ 1/2″ fire retardant polyurethane foam, density 2.6 lbs per cubic foot. 6 fasteners per panel min.

Fabric to foam adhesion, custom fabrics

See fabric swatches for standard available fabrics. Specialty fabrics may be available if they conform to our unique formulated 3 in 1 foam adhesion technology.

Typical fabric construction

Marquesa Lana Olefin yarn, 100% solution died, continuous filament Olefin. Shall have 13 fill picks per inch, 13 warp ends per inch, weight 16 Oz per linear yard, including backing.

Fabric fit and installation

Fabric will conform to all corners and edges without exposed folds or creases. Fabric and foam pad will be removable for maintenance or replacement if required. Stiching will not be visible.

Hinge mechanisms & testing

The hinge mechanism shall be certified to pass seat cycle oscillation testing, ASTM designation F851-87 test method for for self rising seat mechanism, and sandbag testing. Testing will require a force of 500 lb load, with over 100000 cycles, without failure of sign of wear.

Fire retardancy

All fabric shall meet or exceed class 1 flammability requirements of the US dept of Commerce, standard 191-53 per bulletin # 117, (California)

Material of back

The seat back will feature the most advanced ergonomic design, allowing the user optimum comfort for lengthy durations, while maximising lower lumbar support, shoulder, back and leg curvatures with proper air ventilation to contact areas.

Material of bottom

Seat bottom construction will have ergonomic and longevity features inherant. The front edge of the cushion will permit proper under leg support, and not “flatten” within 10 years of normal use. Cushion will also have conduits in the surface pad design for air to flow while in use.

Chair bottom and back body

Lightly textured surface, constructed double wall, polyethylene plastic w/anti-static compound, wall.125″, rotational blow molded. Parts will be free of voids, and all edges will clean and smooth, with no exposed air holes.

Paint and plastic

Where applicable, Nema LD3, HGS, (General purpose type, .048″ thickness), will be cut and trimmed for durability and smooth handling.